- Call us : 28500167 / 49723616

- Email : info@lucaselectronics.in

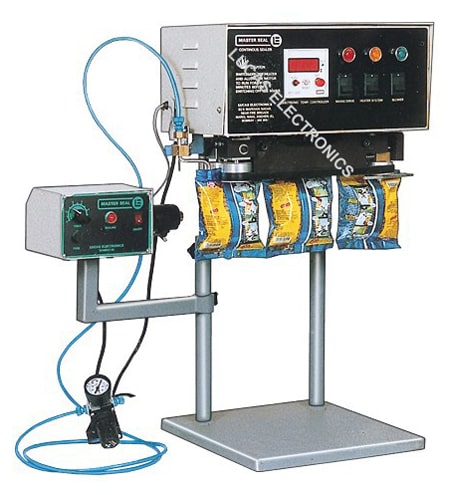

Continuous / Band Sealer Machines

The Lucas Electronics is the pioneer of manufacturing wide ranges of Band sealers/ Continue Sealers since 28 years. These continue sealer is specially designed for multi purpose operation. It consists of a frame, ON/OFF switch, speed regulator (optional), cooling fan, Digital temperature controller, drive & adjustable conveyor and sealing & embossing wheel. The Teflon sealing bands, drive belts and conveyor belt are controlled by one motor. When the on/off switch is turned on, the temperature controller begins heating the sealing blocks. The temperature setting and the speed setting will depend on the type and thickness of material being sealed. The bag will pass through the sealing blocks, cooling blocks and (optional) embossing wheel before being dropped out the end sealed.

Designed for sealing any type of plastic bags of any size, length and thickness up to 20 mil. The maximum seal width is 15 mm. The variable conveyor belt speed is adjustable to accommodate materials of various thicknesses. The conveyer can be raised or lowered and in some models, even tilted to the desired angle. Each machine comes with containing spare band, and set of heaters. Some models can be interchanged easily from horizontal to vertical to free standing positions without any extra kit. Vertical Continuous Sealer with variable speed conveyor, which is Ideal for sealing bags containing powder, liquids, or other small grains.

Easy operating and replacing for parts, most stainless steel parts preventing a tarnished body, being able to adjust the height of the conveyer for working in most situations regardless of the contents in a bag, Self-adjusting pressure system for suitable sealing types according to the thickness of the bags. (Optional) Air suction system being able to keeping the packed products fresh, displaying, storing for a long period of time by sucking out the inner air of the bags.

Operations :

The continue sealer is specially designed for multi-purpose operations. It consists of a frame, an On/Off switch, speed regulator (optional), cooling fan, digital temperature controller, drive & adjustable conveyor and sealing & embossing wheel. The Teflon sealing bands, drive belts and conveyor belt are controlled by one motor. When the On/Off switch is turned on, the temperature controller begins heating the sealing blocks. The temperature setting and the speed setting will depend on the type and thickness of material being sealed. The bag will pass through the sealing blocks, cooling blocks and embossing wheel before being dropped out the end sealed.

Designed for sealing any type of plastic bags of any size, length and thickness up to 20 mil. The maximum seal width is 15 mm. The variable conveyor belt speed is adjustable to accommodate materials of various thicknesses. The conveyer can be raised or lowered and in some models, even tilted to the desired angle. Each machine comes with containing spare band, silicon, and set of heaters. Some models can be interchanged easily from horizontal to vertical to free-standing positions with optional conversion kit.

| Specifications : | |

|---|---|

| Voltage : | 230 volt |

| Power : | 600W |

| Speed : | 6000 mm/min |

| Sealing width : | 6-12mm |

| Temp range : | 0-300ºC |

| Weight : | 28 kgs |

| Size : | 900 x 350 x 500mm |